Industry-specific mechanical engineering industry support solutions.

Industry-specific mechanical engineering industry support solutions.

Blog Article

Leading Tips for Effective Electrical System Troubleshooting

Troubleshooting electrical systems requires a methodical method, based in a detailed understanding of electrical principles and safety methods. The nuances of effective fixing extend beyond mere technological knowledge; understanding exactly how to record searchings for and prioritize safety can significantly influence outcomes.

Understand the Basics

Understanding the essentials of electric systems is crucial for effective troubleshooting, as a strong structure enables technicians to diagnose and fix problems more efficiently. A thorough understanding of electrical principles, such as voltage, current, resistance, and power, is crucial in identifying the origin of troubles. Voltage is the electric prospective difference that drives existing with a circuit, while resistance opposes the flow of current, influencing the total capability of the system.

Familiarity with circuit elements, including resistors, capacitors, diodes, and switches over, is likewise paramount. Each element plays a distinct function in circuit actions and can impact efficiency when malfunctioning. Furthermore, recognizing series and identical circuit configurations is crucial, as these arrangements affect the circulation of voltage and present within the system.

In addition, understanding of safety and security protocols is crucial. Service technicians have to understand possible hazards, such as shock and brief circuits, to apply safe troubleshooting methods. By understanding these foundational ideas, specialists boost their ability to conduct efficient diagnostics and fixings, ultimately resulting in improved performance and integrity of electrical systems. This foundational understanding is the keystone of successful fixing endeavors.

Gather Necessary Tools

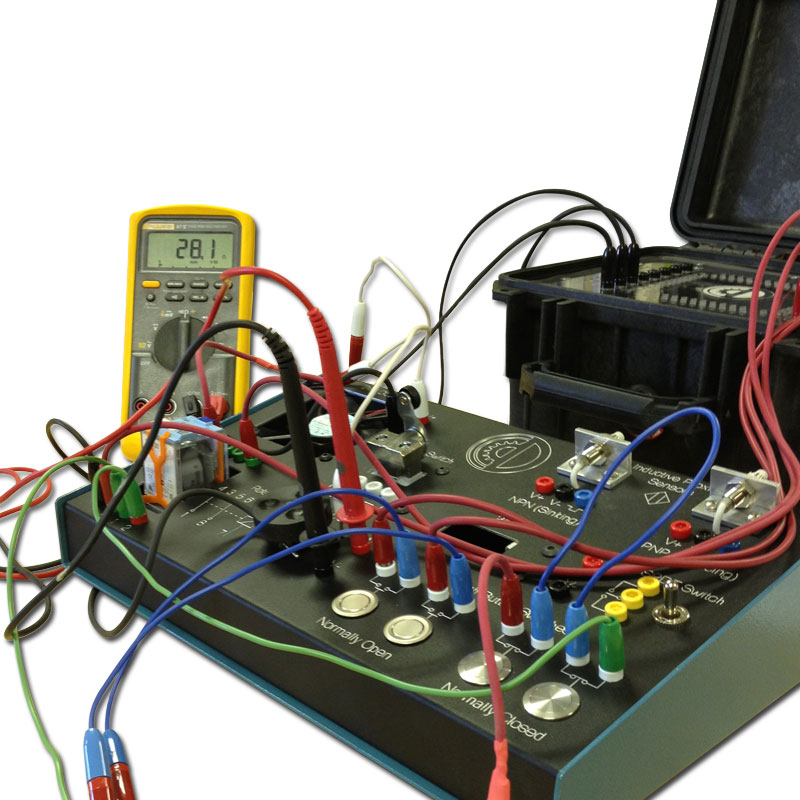

Effective troubleshooting of electrical systems requires the right set of devices to detect and deal with problems precisely. A well-appointed technician can considerably enhance efficiency and effectiveness in determining problems. Important tools consist of a multimeter, which gauges voltage, present, and resistance, enabling for accurate examinations of electrical components. Secure meters are likewise important for measuring existing without separating the circuit, making certain safety and security and comfort.

Additionally, protected hand devices such as screwdrivers, pliers, and cable strippers are essential for securely controling electrical links. It is likewise suggested to have a circuit tester handy to verify the existence of voltage in outlets and wires. For even more complex systems, a thermal imaging camera can assist spot overheating parts, indicating prospective failures.

Adhere To a Systematic Method

Having gathered the proper tools, the next action in fixing electric systems is to comply with a systematic approach. A methodical technique guarantees that professionals can identify faults effectively and accurately, reducing downtime and avoiding unnecessary repair services.

Begin by assessing the system's schematic layouts and requirements. Recognizing the style and operational parameters will give context for diagnosing issues. Next off, separate the issue area by making use of a procedure of elimination. This includes checking each Continued part methodically, starting from the source of power and functioning in the direction of the tons.

Utilize screening devices, such as multimeters and oscilloscopes, to gather unbiased data regarding voltage, present, and resistance at various factors within the system. This empirical evidence will certainly direct your troubleshooting initiatives and assist to validate or remove prospective root causes of failing.

In addition, take into consideration environmental elements that might influence the system's performance, such as temperature level fluctuations or wetness ingress. A comprehensive assessment of electrical wiring, links, and elements will make sure that all possibilities are represented.

Document Your Searchings For

Comprehensive paperwork is crucial in the troubleshooting procedure of electric systems. This practice not only aids in comprehending the root cause of the issue however additionally serves as a referral for future troubleshooting initiatives.

In addition, maintaining a log of components replaced or repair work done is vital. This info supports supply monitoring and can assist assess the long life and dependability of particular browse around here components.

Inevitably, the paperwork process need to be complete yet concise, making it possible for simple retrieval and testimonial - electrical system troubleshooting. By prioritizing detailed paperwork, service technicians can create a useful understanding base that not only help in present troubleshooting but likewise empowers future upkeep efforts, thereby boosting general system integrity

Prioritize Precaution

Recognizing the integral risks connected with electrical systems is important for ensuring security throughout troubleshooting. Electrical shock, burns, and devices damage are just a few of the prospective threats that service technicians encounter. Prioritizing precaution is not just a legal obligation yet also a moral imperative that safeguards both the service technician and the surrounding environment.

Before starting any troubleshooting task, professionals should don appropriate personal protective devices (PPE), consisting of shielded gloves, safety glasses, and flame-resistant garments. Making certain that the workplace is dry and totally free of mess can substantially lower the threat of crashes. It is necessary to de-energize circuits prior to beginning any type of job, confirming that they are not live through the usage of a multimeter or voltage tester.

Establishing clear communication protocols with employee is also vital; this ensures that everyone knows potential hazards and the condition of the electrical system being worked with. Lastly, having an emergency response strategy in area can verify very useful in case of an occurrence. By focusing on precaution, service technicians can efficiently reduce threats and promote a much safer workplace.

Verdict

Reliable electric system repairing depends on a detailed understanding of fundamental concepts and a methodical strategy. By collecting important devices, adhering to methodical assessment strategies, and thoroughly documenting searchings for, the troubleshooting process ends up being much more reliable and trusted. Prioritizing precaution ensures the well-being of people involved and the stability of the electrical system. Carrying out these strategies will boost the troubleshooting experience, bring about quicker resolutions and enhanced functional efficiency in electrical systems.

Report this page